Through-Hole Technology

Despite the fact components have become increasingly smaller — and that surface-mount technology (SMT) and chip-on-board technology (COB) have shown very strong growth — the older conventional technology, through-hole technology (THT), is still indispensable. Liad Electronics has more than 35 years of experience in THT.

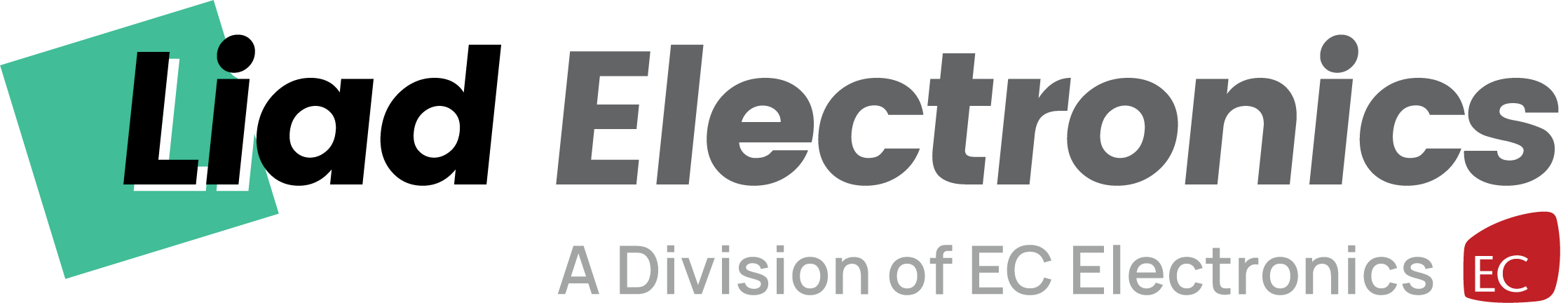

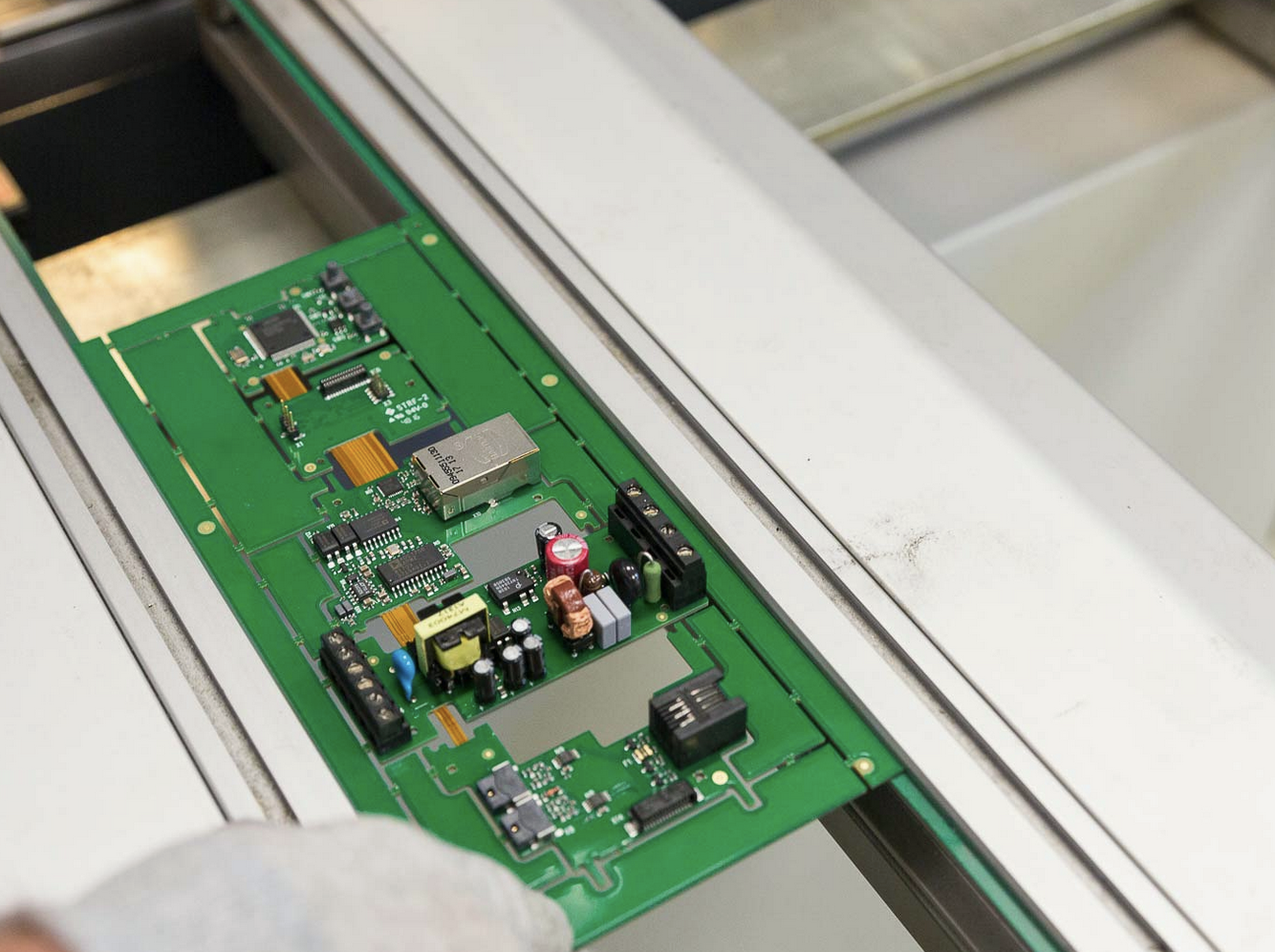

Hand soldering

If wave and/or selective soldering is not possible, we place the components by hand. Our THT department consists of IPC-A-610 certified employees who assemble completely manually.

Wave soldering

Wave soldering is a particularly secure, machine form of soldering that guarantees a high-quality solder connection. Wave soldering takes place entirely under nitrogen, which has the advantage of minimal contamination of the product, meaning a cleaner product.

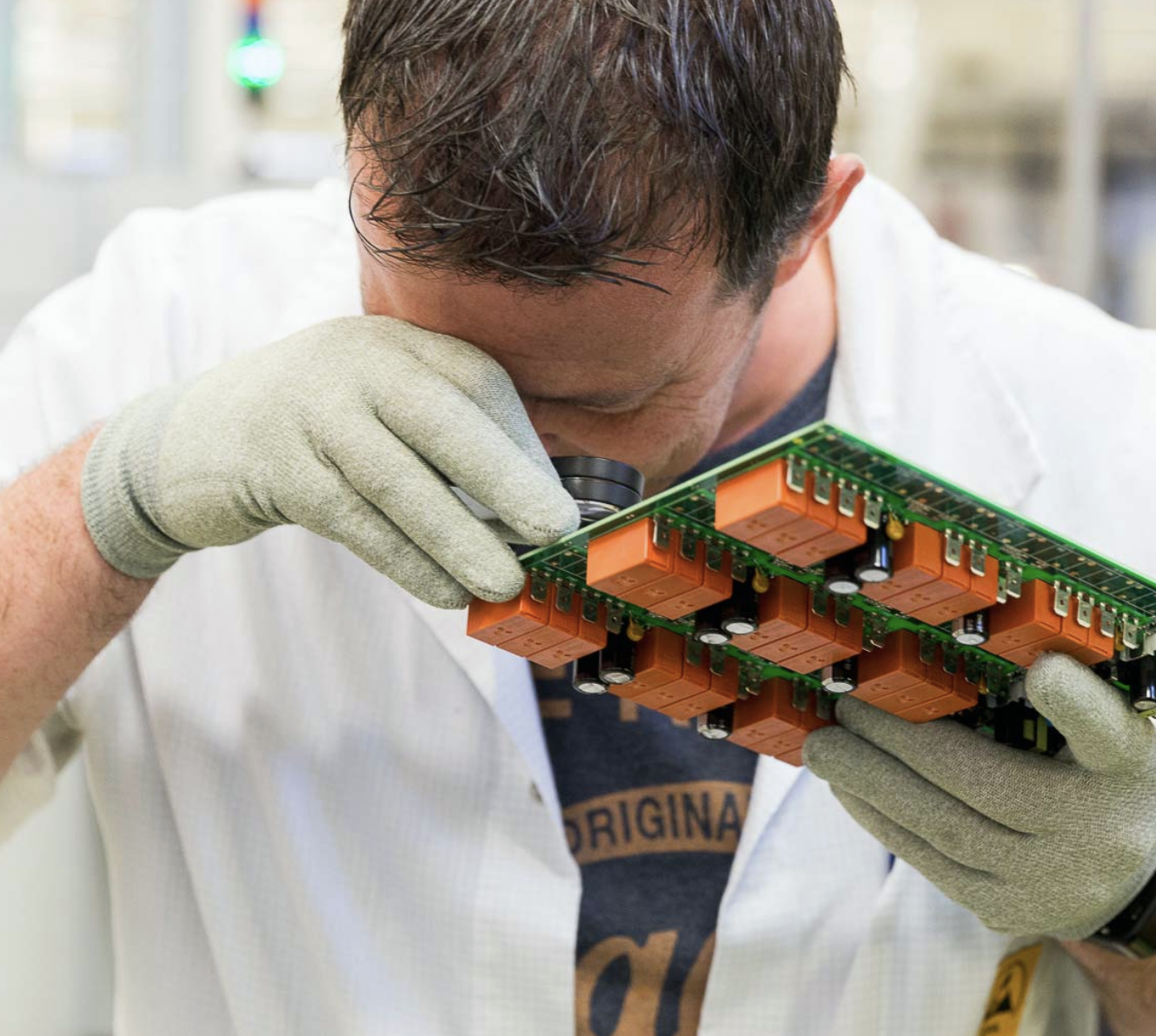

Selective soldering

Selective soldering of through-hole components has the advantage that you can solder with limited space on double-sided mounted SMA PCBs. The machine works faster than hand soldering and can deliver greater production. This method is, therefore, faster and cost-efficient.

Automatic soldering

Both wave and selective soldering are performed automatically to ensure optimal quality and reliability. Both processes are lead-free.

Why us?

We are experts in PCB assembly. The unique combination of our friendly customer service team, state-of-the-art machinery and experienced electronics manufacturing engineers means we can deliver your project to an exceptional standard.

From simple high-volume projects to more complex low-volume projects, we manufacture to your needs — working with you every step of the way to produce and end product that meets your exact requirements.