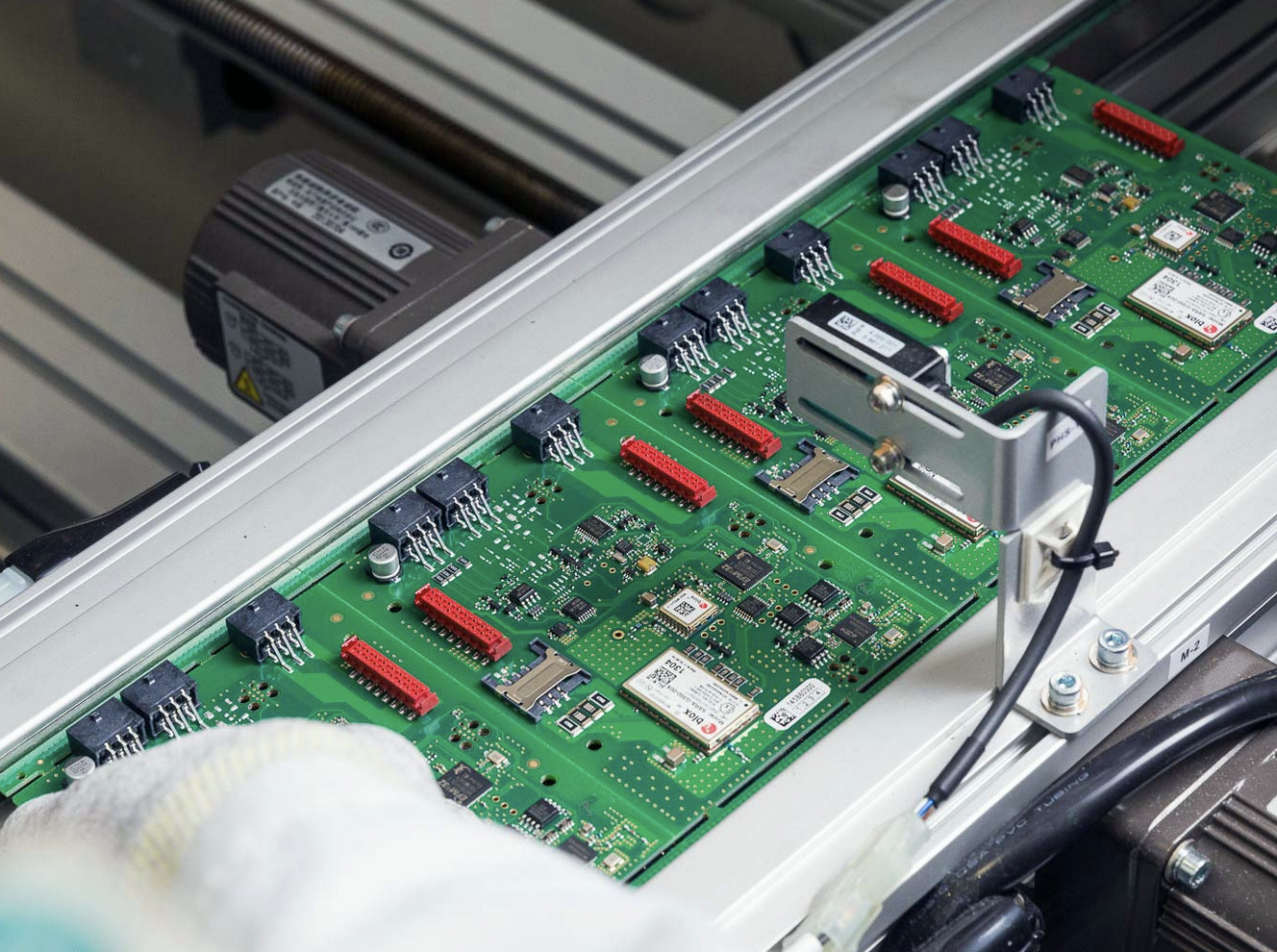

Testing & Programming

The increasing complexity of electronics products requires increasingly extensive testing methods to verify quality and functionality. Liad Electronics has its own test department where we can carry out any desired method of testing.

What is possible?

Assembled. The product is delivered according to the agreed price, standard and quality, but there is a chance that the product has a functional problem.

Functional. The product is delivered, as assembled, according to the agreed price, standard and quality. Depending on the test coverage, the product has significantly less chance of functional problems and can, therefore, be used immediately.

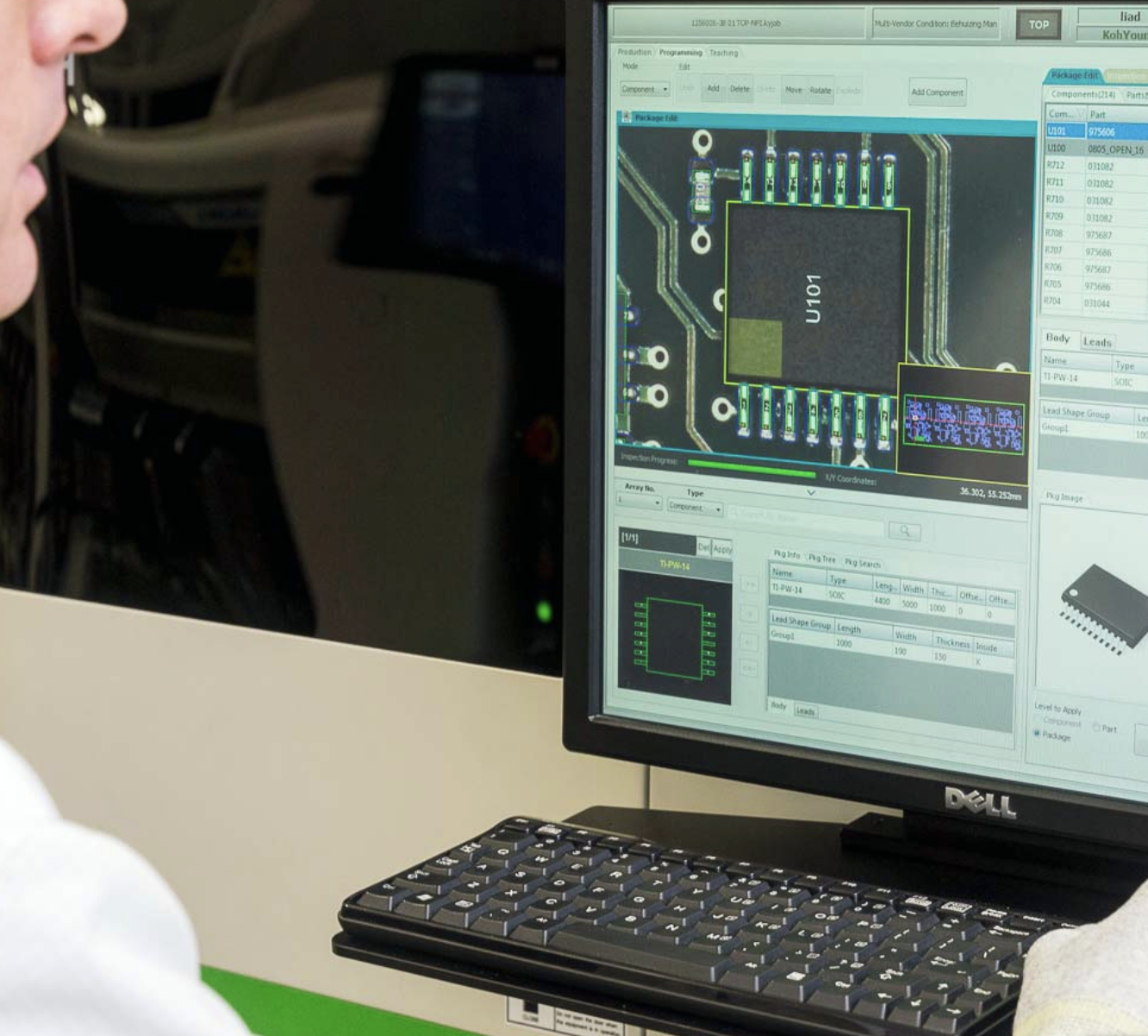

Process control

At Liad Electronics, our philosophy is to safeguard the electronics manufacturing processes through process controls, such as automated material management and identification, solder paste volume inspection (SPI) and automatic 3D inspection (AOI).

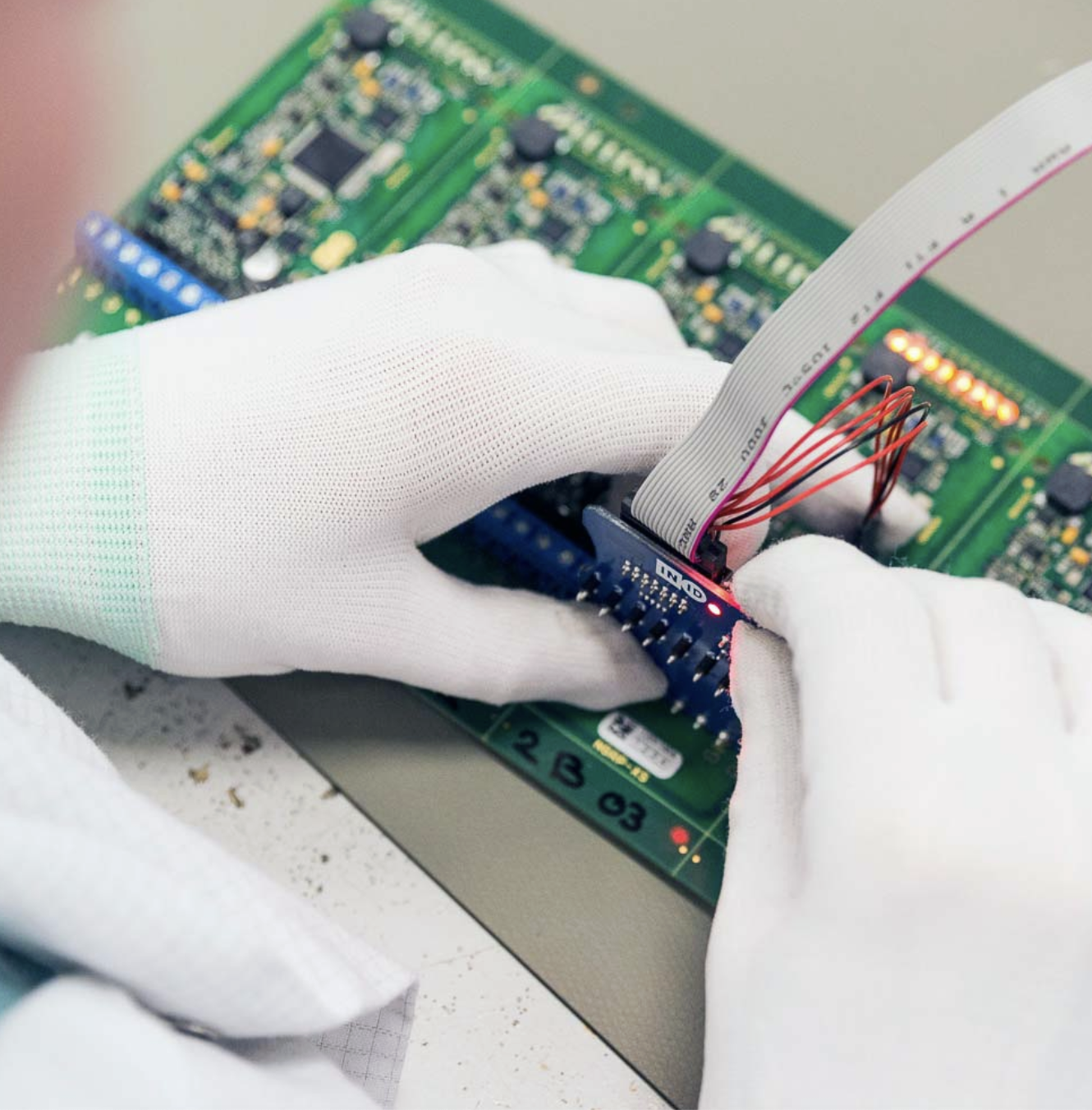

Our functional tests

Application test. When we test with application software, this usually only gives a go or no-go message without error diagnosis. This has the disadvantage of limited coverage and high repair costs, but the advantage is the low investment with limited initial costs.

System test. This process is the same as the application test but with error diagnosis and lower repair costs.

Production test. From functional component groups, the test approach is defined based on a standard and extensible test platform. The coverage level and acceptance criteria are agreed with the customer. Despite the higher initial costs, downtime is reduced and productivity improved. Good diagnostics and traceability are available, and a short improvement loop is created so that the process can be optimally organised.