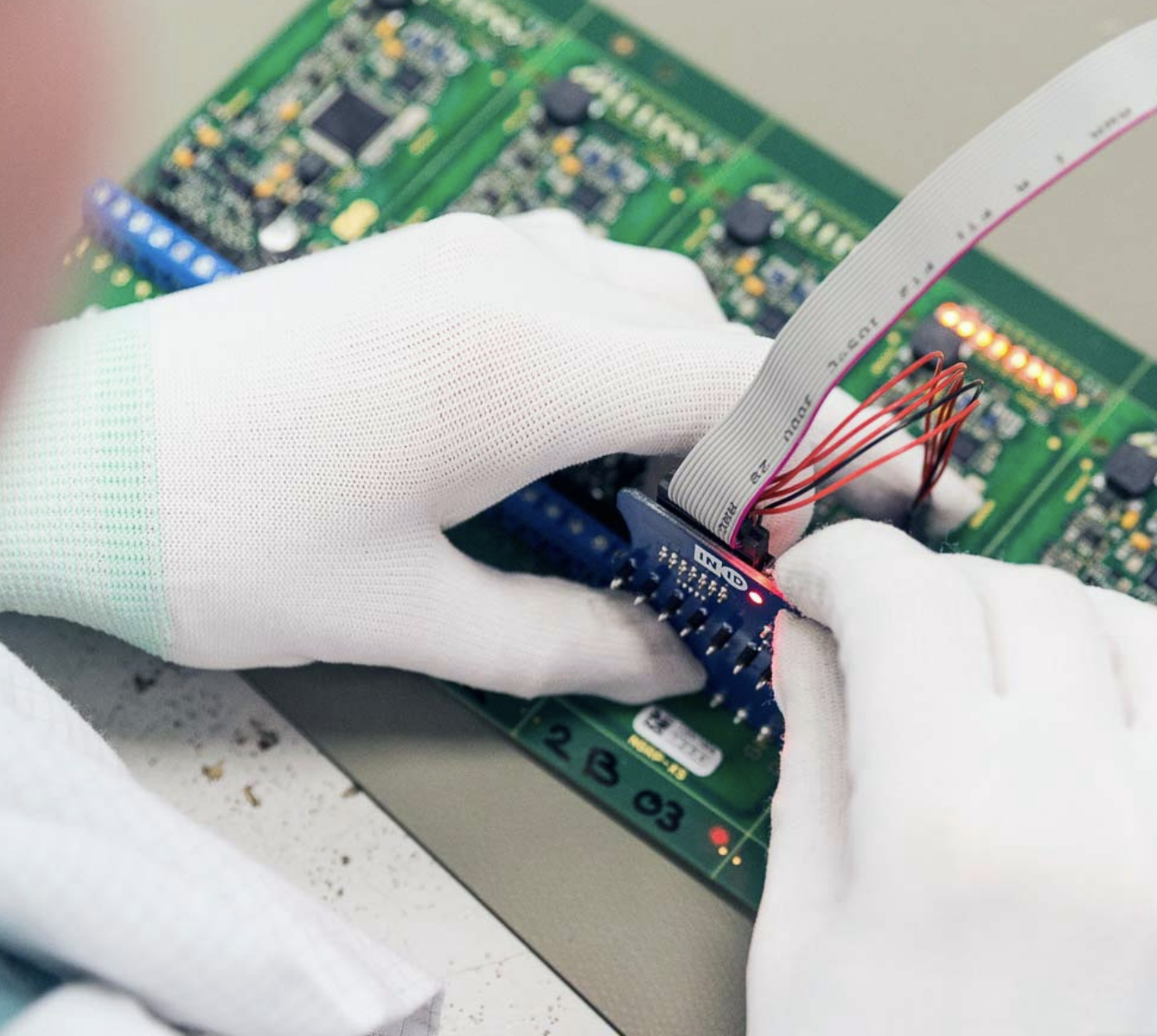

Final Assembly

Liad Electronics relieves your worries by offering a completely assembled and tested product.

As well as manufacturing printed circuit boards (PCBs) and cable assemblies, our experienced and qualified electronics experts can also mount the assembled PCBs into the selected housing, test them and further assemble them into a final product.

We take care of the entire process from A to Z, so you only require one point of contact for your electronics manufacturing project: Liad Electronics.

Possible finishing operations

We can perform the following operations:

- Module construction. Final assembly in the housing with cable assembly, mechanical assembly and packaging (up to adding an instruction manual).

- Modifications. We have the knowledge, equipment and space for a variety of modification and adjustment work.

- Service and Repair. Thanks to the knowledge we have gained of your product during the production phase, service and repair runs go much more smoothly.

We can also carry out the following post-processing:

- Cleaning. After installation under dust-free conditions, we clean with ionised air and package immediately.

- Coating. Applying a special coating to prevent condensation and weather influences.

- Potting. Pouring of modules and potting can be arranged.

Why us?

We are experts in electronics manufacturing. The unique combination of our friendly customer service team, state-of-the-art machinery and experienced electronics manufacturing engineers means we can deliver your project to an exceptional standard.

From simple high-volume projects to more complex low-volume projects, we manufacture to your needs — working with you every step of the way to produce and end product that meets your exact requirements.