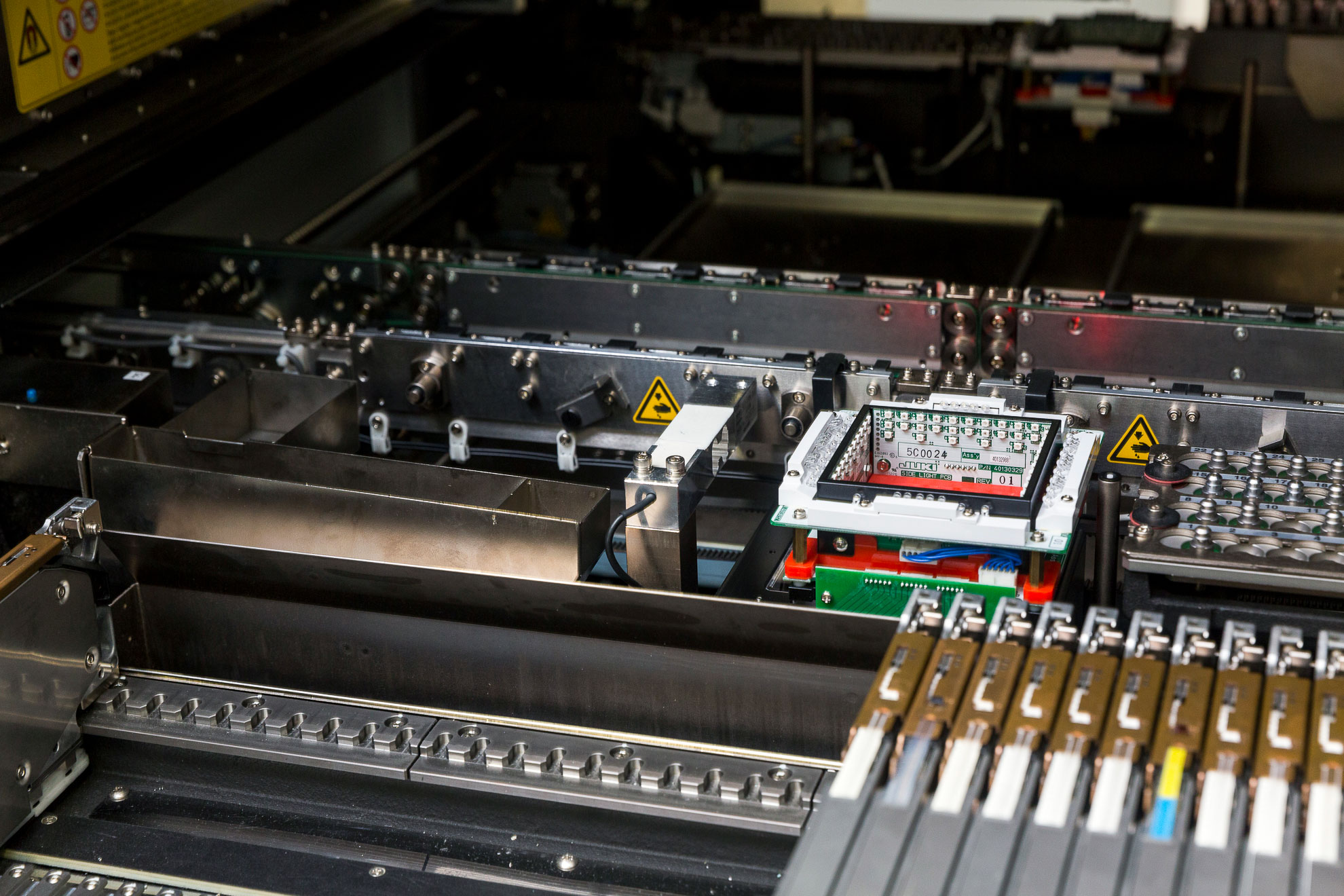

Surface-Mount Technology

Over the years, parts of technical devices and, ultimately, the devices themselves, have become smaller. This process, also called miniaturisation, ensures that surface-mount PCB assembly is now carried out completely by machine.

The SMT components are placed very accurately by fully automated ‘pick-and-place’ equipment. An advanced optical recognition system controls and checks the correct placement.

At Liad Electronics, we only use the most modern surface-mount devices. Our line of surface-mount devices encompass a total of three placement machines, including for 3D automatic optical inspection. This, combined with our SMT team’s large capacity and organisation, allows us to work quickly and flexibly, resulting in shorter production times without sacrificing quality or cost-effectiveness.

We can process all currently available SMT components.