Industrial Controls

The manufacture and full product build of industrial electronics, which cover a broad range of sectors and applications, remains a core focus for us.

Thanks to the growth of connected internet of things (IoT) electronics and the emergence of Industry 4.0, we are now starting to see an increase in automation, artificial intelligence and big data analytics within this market. Robotics has also become integral across industrial applications.

Until recently, robots were primarily used to assemble cars in automotive factories. However, as technology progresses, so too does the scope of robotics. Robotics lends itself well to a range of applications where the task at hand is time-consuming or lacking resources, requires high levels of accuracy and consistency or is too dangerous for a human to do. For example, in a warehouse setting, robotics can pack goods quickly and more efficiently than human workers. Combined with IoT, robotics has the potential to bring connectivity and automation to ‘smart’ factories around the world.

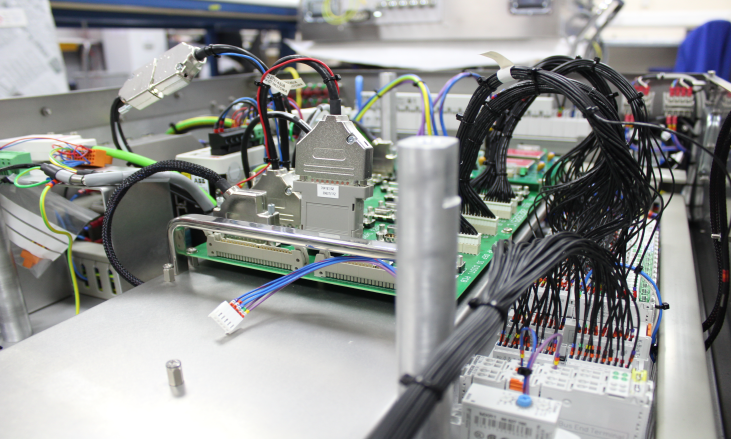

Complex & high-performance electronics

As well as robotics, industrial applications consist of various technologies and can often be some of the most challenging to produce. This field demands complex and high-performance electronics and systems, so it is important that all the parts and processes involved — whether it be a PCB assembly or prototype cable assembly — fit the bill.

Much of what we manufacture at Liad Electronics is embedded within safety-critical or failsafe systems, where control, consistency and product reliability are paramount. This is why we only manufacture electronics to the highest quality levels and IPC-A-610 and IPC/WHMA-A-620 standards of workmanship. Our clients rely on us to deliver exceptional electronics manufacturing services, and we are proud to meet this expectation consistently.